The Heikkila Chemistry and Advanced Materials Science (HCAMS) building is a 56,000 square foot research and laboratory building that will serve as a teaching resource for students from across disciplines and house a research lab, the Advanced Materials Center. The new building will help UMD meet the demand for STEM graduates in our region, along with upgrading important research facilities.

Research buildings use more energy than standard office or classroom buildings, so careful design considerations make this a highly energy-efficient building. However, the building will add around 3% to the campus greenhouse gas footprint, making energy efficiency and renewable investments even more important into the future. Green features of the HCAMS building include:

Energy Efficiency

This research building is quite energy efficient; B3 and SB2030 target for a research lab building is 347 KBTU/SF/year, and the predicted energy use of the building is 248.24 KBTU/SF/year, making the building nearly 30% more energy efficient than a standard design.

Heating and cooling in the building is accomplished through connection to existing campus steam and chilled water districts.

Exhaust air from the building flows through a plate heat recovery system, to retain heat from outgoing air to precondition the incoming, outdoor air.

Non-laboratory ventilation systems use Variable Flow Systems to save energy when occupancy is low in the building.

Laboratories have variable flow fume hoods with sash control systems

All of the lighting, both exterior and interior, are low-wattage LEDs, with vacancy and occupancy sensors throughout the building.

Building is connected to campus through a skywalk, to ease access and aid pedestrian safety

- Exterior LED lighting:

- Fume Hood sash control:

Renewable Energy

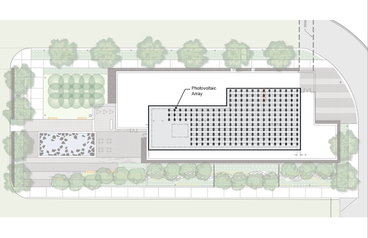

50-kilowatt ballasted solar array on roof (modules are from SolarWorld, Sunmodule Plus, SW 290-300)

Water and Stormwater

Low-flow faucets (1.5 gallons per minute), urinals (0.5 gallons per flush), and toilets (1.28 gallons per flush)

Design for stormwater treatment aimed to deal with runoff from most storms on site and includes: a series of stormwater swales provide biofiltration treatment, pervious pavers in main entrance area from Lot B, and lots of vegetation around the site.

Materials

Long-lasting materials chosen for exterior including: zinc shingles, aluminum, and ironspot face brick. Exterior photo:

- During construction, the project was tracking at 97% of construction materials being recycled. Materials are sorted - from wood to metal, cardboard and even concrete- for reuse, repurposing, or recycling. Recycling at the site will be tracked until the end of construction.

Plenty of windows allow daylight into even the most interior areas of the building, which also allow students and visitors to see applied chemistry in action.

Careful selection of interior finishes and materials avoided volatile organic compounds.

The polished concrete flooring is easily maintained, and durable against chemical spills and stains.

Louvers for the building purchased from Industrial Louvers, the first U.S.-based manufacturer to receive the Just Label from International Living Future Institute. Their sustainability practices focus on lessening manufacturing impacts to the environment.

Basalt is used outside as edging, and is an accent feature outdoors leading to the unique stormwater system.

More information:

Visit the webcam to watch the HCAMS construction progress!

View a presentation about HCAMS given by Dr. Andrea Schokker (UMD Civil Engineering) and Terri Ulrick, AIA, LEED BD + C, BWBR, at the October 2017 Building Green Conference, in Duluth, MN

View a short Sneak Peak video